What is the 5S Process?

Have you ever lost something, looked for it, not found it, replaced it, and then found the lost item the next day? This is a very simple example of how being disorganized can affect time, money, and efficiency. The 5S tool is a 5-step management process created to help people get and stay organized.

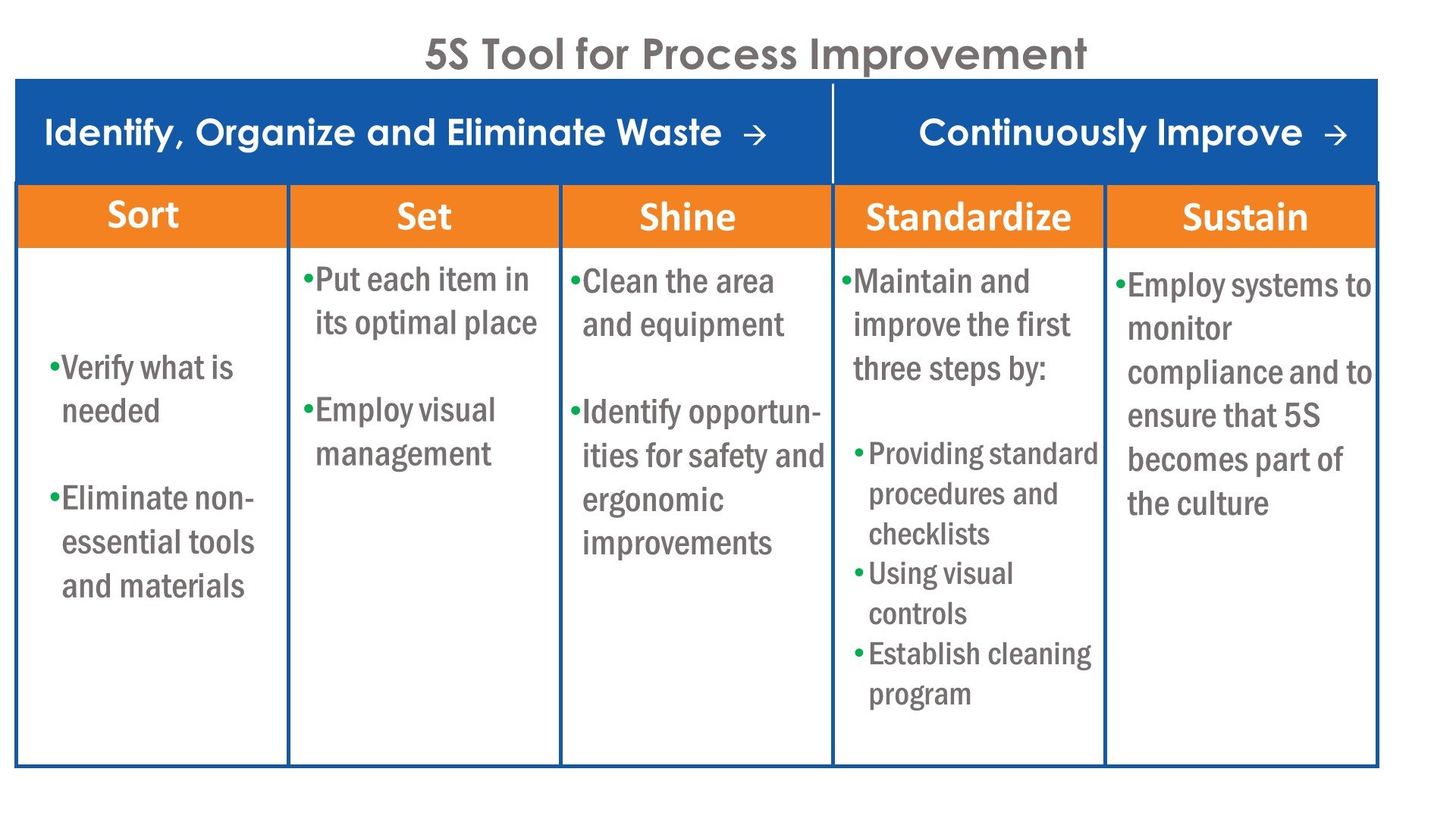

The 5S technique refers to organizing a workplace following a logical, five-step cycle:

- Sort

- Set in order

- Shine

- Standardize

- Sustain

What are the 5S Benefits?

If those outcomes appeal to you, you might want to consider how the 5S management tool might benefit you and your employees. Let’s dive into the details and learn this methodology for organizing your workplace through the steps of sort, set in order, shine, standardize, and sustain.

How do I Implement the 5S Process?

Just like eating an elephant, implementing a 5S strategy must be done one “bite” at a time. This means you need to select an area in which you will begin. Don’t take on too much at first. Instead, find a workstation, office, or storage room that can benefit from organization, and off you go!

Sort

The first step to employing the 5S management tool is to sort the supplies, tools, equipment, containers and materials found in the area. Over time, processes change, and there may be items that were used some time ago that are now obsolete and cumbersome.

Each item should be evaluated for its:

- Purpose

- Frequency of use

- Users

The best people to make these evaluations are the people who work in the area the most. They should ask, “Why is this here, how often is it really used and who is using it?” The answers to these questions can guide the workers to a determination of one of the following options for each item:

- Keep in the area

- Take to another department

- Move to a storage room

- Throw away or recycle

Occasionally, employees may not know the best course of action to take. In that case, they may choose to tag an item with information such as where and when it was found and the name of the person applying the tag. Tagged items are then placed in a designated area in the workplace to await someone who needs it. If a determined amount of time passes, such as two months, and the item was never needed, then a decision for disposal can be made, and the item may be removed from the area.

Once the sorting is done, only useful items remain in the area to be set in order.

Set in Order

Now it is time to organize what is left — the meaningful materials necessary to complete the activities in the work area. Employees should think through several key ideas as they begin to determine assigned places for the needed materials, tools, supplies and other items, including:

- Users: Knowing who uses the item is the main factor to consider when deciding where an object should be placed when not in use. It must be readily accessible if it is a commonly used item.

- Workflow: The flow of the tasks could also be an important input as to where items are placed in relation to each other. Likewise, things that are used less frequently might be stored in a less accessible location than the items that are needed daily.

- Related items: Things that come in sets, or that are otherwise related or similar are often placed near each other, so users know to go to that area to get any of that type of thing.

- Logical places: Use simple logic to cut down unnecessary movement. Keep items needed for a certain task as close as possible to the area where that task is performed.

Another aspect of the step set in order is to consider what may need to be added to the area to make it more orderly. You may need additional storage containers and visual management tools such as tape on floors or workbenches, labels for shelves, drawers or bins, shadow boards and signs.

The point is to organize what is really needed so that all users can find what they need when they need it. And when everything has an optimal place and is kept in its place, it is much easier to keep the area clean.

Shine

Companies that are new to 5S might complete these first 3 phases and think, “We did it!” The areas are uncluttered, organized and clean, and that is something to celebrate, but 5S doesn’t stop there. Without standardizing the process, it is likely that old habits will prevail, and the work areas will return to a less than desirable state.

Standardize

Companies that are new to 5S might complete these first three phases and think, “We did it!” The areas are uncluttered, organized and clean. While that is something to celebrate, 5S doesn’t stop there. Without standardizing the process, old habits can prevail, and the work areas will return to a less-desirable state.

The standardize phase is what makes 5S so much more meaningful than just an annual clean-up initiative. During this step, companies will create standard operating procedures to ensure that new habits are established and that workplaces will remain in good shape.

A few examples of standardization for 5S include:

- Daily 5S checklist

- 5S chart of instructions

- Schedule of housekeeping activities

- Written 5S compliance procedures

Sustain

Ultimately, 5S becomes a part of a company’s culture, not just a program.

How does the 5S Process Relate to ISO 9001?

Many organizations seek to integrate the ISO standards with the 5S process. Though using 5S tools is not a requirement in ISO 9001:2015, it may be useful in showing evidence to your auditor that you are taking the requirements in the standard seriously.

Clause 4.4.1 of the ISO 9001 Standard and 5s

Clause 4.4.1 requires the organization to create and continually maintain its quality management system, dedicating the appropriate resources and continually reevaluating processes to make them more efficient.

Following the 5S process can help in this respect by ensuring you regularly consider the resources and processes required for various operations.

ISO 9001 Clause 8.5.1d and 5s

Likewise, clause 8.5.1d requires a suitable infrastructure for operations, which involves keeping the workplace and infrastructure clean and well organized.

ISO 9001 Clauses 7.1.3 and 7.1.4 and 5s

The 5S technique can help with implementing clauses 7.1.3 and 7.1.4. These clauses address the Infrastructure and the Environment for the Operation of Processes.

According to these ISO 9001 standard clauses, the infrastructure requires regular maintenance and adequate cleanliness so operations can continue efficiently. For example, cleaning debris and oil off of machinery helps it continue running smoothly. Also, maintaining a clean, comfortable work environment helps your team do their best work.

The 5S Workplace

When work areas are functional and clean, companies have a better chance of achieving positive process results, higher quality, increased productivity, reduced cost, increased employee satisfaction, and a safer workplace. 5S is a methodology for realizing these benefits.

Three initial steps to implementing 5S are:

- Sort: verify what is needed, eliminate non-essentials

- Set in Order: determine optimal places, use visual management

- Shine: Clean area and equipment

The last two phases of 5S are about making the changes last and having organization and cleanliness become part of the company’s culture. They are:

- Standardize: Provide procedures, checklists, charts, and cleaning programs

- Sustain: Monitor the 5S methods and make 5S part of the culture

With these procedures implemented and monitored, you can expect that your workplace will be maintained suitably and lend itself to being a valuable asset. If you’re looking for assistance using 5S as part of your ISO 9001 implementation, contact Core Business Solutions today for a consultation.

Core Business Solutions can help you Implement a 5S System

About Scott Dawson

Since 2010, Scott Dawson, President of Core Business Solutions, has been an active voting member of the U.S. Technical Advisory Group (TAG) to ISO Technical Committee 176 (TC 176). TAG 176 members meet to discuss and develop U.S. positions for Quality Management standards, including ISO 9001:2015, which will be revised in 2026.